Applications

- Architectural glass

- Touch screens and flat monitors

- OLED applications

- Smart-glass applications

- Transparent antistatic foils

- Photovoltaic cells

- De-icing and heating applications

- Batteries

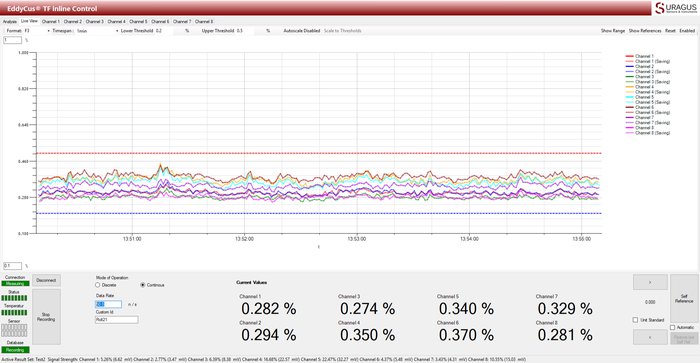

The EddyCus® TF inline series combines standardized and customized hardware for integrated quality assurance in automated production lines. Testing tasks for inline applications involve thickness and sheet resistance measurement. The eddy current based technology facilitates the comprehensive monitoring of deposition processes over the entire production width. The available hardware platform provides a high degree of variability and flexibility according to specific customer requirements. This non-contact inline solution is beneficial for quality assurance for:

| Transparent Thin Films | Metallic Thin Films |

|---|---|

| ITO (Indium Tin Oxide) | Aluminum |

| Carbon nano tubes and nano buds | Molybdenum |

| Graphene films | Silver |

| Metal nano wires and nano grids | Copper |

| Nano particle films | and many more |

EddyCus® TF inline comprises sheet resistance and layer thickness measurement solutions for inline measurement quality assurance and process control.

| EddyCus® TF inline | ||

|---|---|---|

| Measurement Gap Size | 1 / 5 / 10 / 25 / 50 mm (other on request) | |

| Number of Sensor Pairs | 1-99 | |

| Subtrates | Glass/PET-foils/wafer | |

| Conductive Layers | Metals / TCO / CNT / Nanowires / Graphene / Grids | |

| Sheet Resistance Range Covered by Every Sensor | 0.001 – 10 Ohm/sq < 2% accuracy 10 – 100 Ohm/sq < 3% accuracy 100 – 1,000 Ohm/sq < 5% accuracy |

|

| Environment | Ex-vacuo/in-vacuo < 60°C/140°F (on request < 90°C/194°F) |

|

| Sample Rate | 1 / 10 /50 /100 /1,000 samples per second (higher on request) | |

| Thickness | 2 nm to 2 mm in accordance with sheet resistance | |

| Further Integrated Measurements | Substrate thickness and temperature/ optical transmission |

|

| Further Integrated Availabe Features | Hardware trigger/DMC or bar code reader | |

REQUEST QUOTE